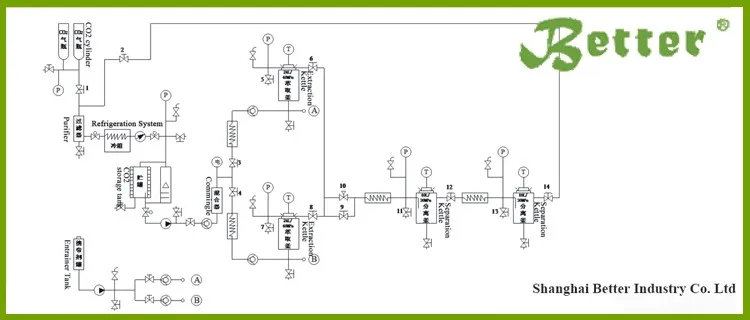

The device is used for the extraction of material (solid or liquid)under high pressure and suitable temperature extraction.Changing conditions in the separation kettle, the dissolved substances will resolve in order to achieve the purpose of separation.Supercritical CO2 extraction equipment includes several parts: extraction kettle, separation kettle,commingle, CO2 high-pressure pump, entrainer pump, refrigeration system, heat exchange system, CO2 storage tank, CO2 level gauge,purification system, flow meter, temperature control system, safety protection system etc.The supercritical CO2 extraction is specially suitable for extraction of fat-soluble and heat sensitive substances with high boiling point.Take CO2 as the solvent to make extraction and purification upon a lot of products such as biological products, foodstuff and medicines.

1) Intermittent or continuous work,co-solvent can be added if the request;

2) CO2 can be recovered and reused;

3) Pressure and temperature can be designed according to demand;

4) Can custom made into PLC or computer control.

| APPLICATION | Supercritical CO2 Oil Extraction Machine/Equipment |

| Agriculture Food | Extraction of pesticides and soil contaminants. Separation of fats and contaminats, flavors. |

| Pharmaceutical | Extraction of active components, preparation of natual products, viamins. |

| Cosmetic | Extraction of fragrances and oils. |

| Laundry | Dry cleaning of garments. |

| Mechanical | Degreasing parts, precision cleaning of high-value components. |

| A wide range of industries for the extraction of natural products for the food additives(such as ginger, large bolt, cinnamon, anise, hops, pepper, cumin,etc.), drugs(such as Artemisia annua vegetarian, magnolia, Angelia, etc.), health care(such as sea buckthorn, samara, pomegranate, lycopene, etc.) | |

| SPECIFICATIONS | |||||||

| No. | Model | Capacity | Pressure(Mpa) | Temperature(℃) | Power(KW) | CO2 Pump Flow(L/H) | Dimension(mm) |

| 1 | HSFE0.5 | 0.5L*1 | 50 | 85 | 10 | 50 | 2500*2500*1600 |

| 2 | HSFE1 | 1L*1 | 10 | 50 | 2500*2500*1600 | ||

| 3 | HSFE5 | 5L*1 | 18 | 50 | 2500*2500*1600 | ||

| 4 | HSFE10 | 10L*1 | 40 | 18 | 100 | 3000*2500*1600 | |

| 5L*2 | |||||||

| 5 | HSFE20 | 10L*2 | 25 | 200 | 3000*3000*1800 | ||

| 6 | HSFE30 | 10L*3 | 30 | 210 | 5000*4800*1800 | ||

| 7 | HSFE48 | 24L*2 | 45 | 400 | 5000*5000*4200 | ||

| 8 | HSFE96 | 24L*4 | 58 | 600 | 5800*5000*4200 | ||

| 9 | HSFE100 | 50L*2 | 60 | 800 | 6200*6000*4500 | ||

| 10 | HSFE120 | 30L*4 | 60 | 800 | 6800*6000*4500 | ||

| 11 | HSFE150 | 50L*3 | 63 | 1000 | 7200*6000*4500 | ||

| 12 | HSFE200 | 50L*4 | 65 | 1000 | 7800*7000*4500 | ||

| For capacity above 200L, it will be custom made. | |||||||

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil, etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5. Can the CO2 be reused?

YES. CO2 can be used in circulation.

6. Can your machine work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

This unit is popular in extraction of essential oil from plants,flowers,leaves,wood, such as rose,lavender,eucalyptus leaves,lemongrass,citronella,sandalwood, agilawood etc.by steam distillation or water distillation, the steam passes through plants material and vaporizes oil,mixtures of steam and oil vapors go into the condenser.after the cooling,oil formed.this is the ideal device for you to make essential oil no matter for laboratory use or batch production.

| Flowers | Rose; jasmine; lavender; chamomile; ylang ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; honeysuckle; violets. |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedar wood; rosewood; agarwood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine . |

| Seeds | Cloves; almonds; cardamom; carrot seed; pomegranates; pepper; capsicum ; fennel. |

1) Model: EC20 Citronella Oil Distillation Plant

2) Power: 4.5KW (3 phase, 380v/50Hz)

3) Volume of distillation pot: 20L(according to demand of customers)

4) Heating area of distillation pot: 0.4M2

5) Condensation area of condenser: 0.75M2

6) Power of heater: 4.5KW

7) Size: 1200x700x1500mm (according to demand of customers)

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

BETTER EC20 essential oil distilling equipment is popular in production of Chinese medicines,health products,biological drugs,cosmetics and food .This essential oil Distill equipment uses technology and chemical separation,can extract plant components efficiently by steam distillation , have good effect in collecting essential oil from palnts.

1. This essential oil equipment is by steam-distillation to reach the extraction of essential oils.

2. Easy operation. One people can operate this rose oil extraction equipment easily .

3. High efficiency. This essential oil equipment can quickly reach 100°C high temperature under the conditions of cleanness, safety and atmospheric pressure. If required, with vacuum pump, the extraction speed of essential oils will be more faster.

4. Compact structure. It covers only about 1.5 square meter.

| Flowers | Rose; jasmine; lavender; chamomile; ylang ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; honeysuckle; violets. |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedar wood; rosewood; agarwood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine . |

| Seeds | Cloves; almonds; cardamom; carrot seed; pomegranates; pepper; capsicum ; fennel. |

| Model | HEC10 | HEC20 | HEC30 | HEC50 | HEC100 | HEC150 | HEC200 | HEC300 |

| Voltage | 10V | 20V | 30V | 50V | 100V | 150V | 200V | 300V |

| Power | 4.0KW | 4.5KW | 5.5KW | 9KW | 12KW | 14KW | 25KW | 25KW |

| Specifications |

1. Steam extraction part is popular with the structure of basket-in-water 2. The operation part has adopted PLC or touch screen control system, this accords to customer’s demand. 3. This unit is automatically operate. 4. All kinds of plants can be the material of essential oil equipment. |

|||||||

1) Model: EC150 essential oil extration equipment

2) Power: 14KW (3 phase, 380v/50Hz)

3) Volume of distillation pot: 150L(according to demand of customers)

4) Heating area of distillation pot: 1.45M2

5) Condensation area of condenser: 1.25M2

6) Power of heater: 14KW

7) Size: 2000x900x2200mm (according to demand of customers)

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

This EC100 Rose Oil Extracting Plant popular in production of Chinese medicines, health products, Biological drugs, cosmetics, and food, it uses the technology of biological and chemical separation, can extract Plant components efficiently by steam distillation, have a good effect in collecting essential oil from plants.

| Flowers | Rose; jasmine; lavender; chamomile; ylang ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; honeysuckle; violets. |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedar wood; rosewood; agarwood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine . |

| Seeds | Cloves; almonds; cardamom; carrot seed; pomegranates; pepper; capsicum ; fennel. |

| Small&Medium size Essential Oil Distiller | ||||||

| Model | Capacity | Power | Diameter of Condenser | Material | Heating Area of Extraction Tank | Condensing Area of Condenser |

| HEC10 | 10L | 4KW | 102mm | SUS304 | 0.3M2 | 0.7M2 |

| HEC20 | 20L | 4.5KW | 102mm | SUS304 | 0.4M2 | 0.75M2 |

| HEC30 | 30L | 5KW | 133mm | SUS304 | 0.45M2 | 0.8M2 |

| HEC50 | 50L | 11KW | 133mm | SUS304 | 0.5M2 | 0.85M2 |

| HEC100 | 100L | 15KW | 133mm | SUS304 | 1.05M2 | 0.95M2 |

| HEC150 | 150L | 17KW | 133mm | SUS304 | 1.45M2 | 1.25M2 |

| HEC200 | 200L | 20KW | 133mm | SUS304 | 1.85M2 | 1.50M2 |

| HEC300 | 300L | 25KW | 133mm | SUS304 | 1.95M2 | 2.00M2 |

| Large Customized Machines | ||||||

| Model | Capacity | Temperature display | Cooling water circulation pump | Crane system | Console | Boiler |

| HEC500 | 500L | The digital temperature control system, with the steam stop valve, drain valves, steam traps, etc. | Cooling water circulation pump, 20tons/H, the cooling water through the pipe into the condenser | 750kg | Carbon steel rust treatment table |

The gas\coal\electric boilers according |

| HEC1000 | 1000L | 1000kg | ||||

| HEC1500 | 1500L | 1000kg | ||||

| HEC2000 | 2000L | 1000kg | ||||

| HEC3000 | 3000L | 1500kg | ||||

| HEC4000 | 4000L | 2000kg | ||||

| HEC5000 | 5000L | 2000kg | ||||

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

BETTER EC20 essential oil distilling equipment is popular in production of Chinese medicines,health products,biological drugs,cosmetics and food .This essential oil Distill equipment uses technology and chemical separation,can extract plant components efficiently by steam distillation , have good effect in collecting essential oil from palnts.

| Flowers | Rose; jasmine; lavender; chamomile; ylang ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; honeysuckle; violets. |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedar wood; rosewood; agarwood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine . |

| Seeds | Cloves; almonds; cardamom; carrot seed; pomegranates; pepper; capsicum ; fennel. |

1) Model: EC20 Citronella Oil Distillation Plant

2) Power: 4.5KW (3 phase, 380v/50Hz)

3) Volume of distillation pot: 20L(according to demand of customers)

4) Heating area of distillation pot: 0.4M2

5) Condensation area of condenser: 0.75M2

6) Power of heater: 4.5KW

7) Size: 1200x700x1500mm (according to demand of customers)

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Introduction:

The circulating water vacuum pump manufactured by our company is a new type of multi-head high-power pumping, one-time anti-corrosion forming shell, five-tap circulating water multi-purpose vacuum pump. The circulating water vacuum pump is designed for internal and external circulating water.

The circulating water vacuum pump has the advantages of no oil, no pollution, high power, low noise, convenience and flexibility, saving water and electricity,

etc. It is multi-purpose.

(1) The machine is equipped with five suction heads for multi-tube operation, which can be used separately or in parallel.

(2) Circulating water vacuum pump has low noise and convenient movement.

(3) The vacuum pump of circulating water is pollution-free. The box body of the machine is made of polyvinyl chloride plastics,

and the shell is made of stainless steel and cold plate electrostatic spraying shell.

This product is a new type of multi-purpose vacuum pump designed with circulating water as working fluid and the principle of negative pressure generated by jet. It can provide vacuum conditions for chemical laboratory and circulating cooling water for

reaction device.

| Model | SHZ-95 |

| Power | 370W |

| Pump Flow | 90L/min |

| Pump Lift | 12M |

| Body Material | Anti-corrosion |

| Voltage | 220V,50/60HZ |

| Sucking rate | 10 L/min *5 |

| Max. vacuum | 0.098Mpa (735mmHg, 0.98bar, 735Torr) |

| Tank capacity | 50L |

| Vacuum port | 5Pcs |

| As circulating pump | Circulating water temperature: 0~25℃ |

| Safety Protection | The product includes check valve to prevent cross-flow |

| Shell Material | PVG with surface electrostatic spray |

| Dimensions | 450*340*870mm |

| Net weight | 37kg |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q: What does BETTER need from me to quote a price?

A: 1).Raw material

2).Production capacity per batch,machine can be customized according to your request for your request.

Q: Do you have machine in stock?

A: No,every machine is customized according to your order.

Q: How long does it take to produce the machine once I place my order?

A: The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 30 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

Q: How will my order be packed, can you provide the installation service?

A: Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Vacuum filter funnel is a device to separate solid and liquid by vacuum negative pressure. In structure, the filter section is arranged along the horizontal length direction, which can continuously complete filtration, washing, drying and regeneration of

filter cloth. Rubber belt filter has the advantages of high filtration efficiency, large production capacity, good washing effect, low moisture content of filter cake, flexible operation and low maintenance cost. Rubber belt filter can be widely used in

solid-liquid separation in metallurgy, mining, chemical industry, paper-making, food, pharmaceutical, environmental protection and other fields, especially in gypsum dehydration in flue gas desulfurization (FGD) has good application.

| Model | VFB |

| Lenght(MM) | 650 |

| Width(MM) | 650 |

| Height(MM) | 1700 |

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q: What does BETTER need from me to quote a price?

A: 1).Raw material

2).Production capacity per batch,machine can be customized according to your request for your request.

Q: Do you have machine in stock?

A: No,every machine is customized according to your order.

Q: How long does it take to produce the machine once I place my order?

A: The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 30 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

Q: How will my order be packed, can you provide the installation service?

A: Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Introduction:

This essential oil distilling equipment is popular in production of Chinese medicines,health products,biological drugs,cosmetics and food .This essential oil Distill equipment uses technology and chemical separation, can extract plant components efficiently by steam distillation, have good effect in collecting essential oil from palnts

1)By steam-distillation to reach the extraction of essential oils.

2)Easy operation. One people can operate this machine easily .

3)High efficiency. Using indirect heating of heat- transfer oil, it can quickly reach 100C high temperature under the conditions of cleanness, safety and atmospheric pressure. If required, with vacuum pump, the extractio speed of essential oils will be ore faster.

4)Compact structure. It covers only about 1.5 square meter.

| Small&Medium size Essential Oil Distiller | ||||||

| Model | Capacity | Power | Diameter of Condenser | Material | Heating Area of Extraction Tank | Condensing Area of Condenser |

| HEC10 | 10L | 4KW | 102mm | SUS304 | 0.3M2 | 0.7M2 |

| HEC20 | 20L | 4.5KW | 102mm | SUS304 | 0.4M2 | 0.75M2 |

| HEC30 | 30L | 5KW | 133mm | SUS304 | 0.45M2 | 0.8M2 |

| HEC50 | 50L | 11KW | 133mm | SUS304 | 0.5M2 | 0.85M2 |

| HEC100 | 100L | 15KW | 133mm | SUS304 | 1.05M2 | 0.95M2 |

| HEC150 | 150L | 17KW | 133mm | SUS304 | 1.45M2 | 1.25M2 |

| HEC200 | 200L | 20KW | 133mm | SUS304 | 1.85M2 | 1.50M2 |

| HEC300 | 300L | 25KW | 133mm | SUS304 | 1.95M2 | 2.00M2 |

| Large Customized Machines | ||||||

| Model | Capacity | Temperature display | Cooling water circulation pump | Crane system | Console | Boiler |

| HEC500 | 500L | The digital temperature control system, with the steam stop valve, drain valves, steam traps, etc. | Cooling water circulation pump, 20tons/H, the cooling water through the pipe into the condenser | 750kg | Carbon steel rust treatment table |

The gas\coal\electric boilers according |

| HEC1000 | 1000L | 1000kg | ||||

| HEC1500 | 1500L | 1000kg | ||||

| HEC2000 | 2000L | 1000kg | ||||

| HEC3000 | 3000L | 1500kg | ||||

| HEC4000 | 4000L | 2000kg | ||||

| HEC5000 | 5000L | 2000kg | ||||

| Flowers | Rose; jasmine; lavender; chamomile; ylang ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; honeysuckle; violets. |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedar wood; rosewood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine . |

Packing:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q:What does BETTER need from me to quote a price?

1.Raw material

2.Production capacity per batch

Q:What is the oil yield?

The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.

Q:Can I use the machine to extract several kinds of raw materials?

Yes,of course.

Q:Can I do extraction test with my own raw material?

Yes,of course.We can do extraction test and send you videos and test report for your Reference.

Q:What heating way does your machine support?

Electricity/gas/wood/steam heating.

Q:What is your material of your machine?

Stainless steel(Standard type is SUS304,it can be customized according to your request)

Q:How long does it take to produce the machine once I place my order ?

Usually the delivery time is 30 working days after prepayment received.

Q:What is the minimum quantity I must order?

We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.

Q:Do you have machines in stock?

No,our machine is produced according to your request.

Q:How will my order be packed, can you provide the installation service?

Packed in plywood case.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Short-Path Fractional Distillation System is a complete turnkey lab solution for your facility. Under normal operation, our two-liter system will produce 200 to 400 ml per hour. We use only the highest quality glass, pumps,heating system and chillers. And your system arrives with everything you need to be successful, including installation and training. Below is an itemized list of what comes with your system.

Short path distillation is a distillation technique that involves the distillate traveling a short distance, often only a few centimeters, and is normally done at reduced pressure. A classic example would be a distillation involving the distillate travelling from one glass bulb to another, without the need for a condenser separating the two chambers. This technique is often used for compounds which are unstable at high temperatures or to purify small amounts of compound. The advantage is that the heating temperature can be considerably lower (at reduced pressure) than the boiling point of the liquid at standard pressure, and the distillate only has to travel a short distance before condensing. A short path ensures that little compound is lost on the sides of the apparatus.

|

Short path distillation |

2 Neck Boiling Flask |

500ml~2000 ml |

5000ml |

10L |

20L |

|

Thermometer Adapter |

24/39 |

||||

|

Short Path Distillation Head |

24/39 |

||||

|

Glass cock/hollow plug |

24/39 |

||||

|

1to 3 Distillation Cow Receiver |

500ml, 24/39 |

||||

|

Round Bottom Flasks |

100ml/250 ml |

500ml |

1000ml |

2000ml |

|

Packing:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1. What’s the operating principle of rotary evaporator?

Under the condition of negative pressure, evaporating flask rotating in the thermostat water bath, which makes solution form a thin film in bottle wall, so as to increase the evaporation area. Evaporating efficiently under low temperature, then condensate recycling through condenser pipe and concentrate to isolate the material to reach experiment requirements.Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +86-2160518061,+86-2160519925

Mobile/whatsapp: +86-18917686969

Skype: joyceleejoe

Email: info@better-industry.com

Address: Bldg. 80, Liandong Ugu, Jiading District, Shanghai, China