Product Details Show

| Model | Hspd-60(b) | Hspd-80(b) | Hspd-100(b) | Hspd-150(b) | Hspd-200(b) | Hspd-230(b) |

| Effective Evaporation Area | 0.05 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Internal Condensation Area | 0.03 | 0.15 | 0.2 | 0.4 | 0.5 | 0.65 |

| Outer Condensing Area | 0.2 | 0.25 | 0.3 | 0.6 | 0.6 | 0.6 |

| Barrel Inside Diameter | 60 | 80 | 100 | 150 | 190 | 220 |

| Constant Pressure Feeding Funnel Volume | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Processing Flow | 0.1∽2.0 | 0.3∽4.0 | 0.5∽5.0 | 1.0∽8.0 | 1.5∽10.0 | 1.0∽15.0 |

| Motor Power | 120 | 120 | 120 | 120 | 200 | 200 |

| Max Rotation Speed | 450 | 450 | 450 | 450 | 450 | 450 |

Other general data

The materials of the feed tank,evaporator ,and the cold trap are all borosilicate 3.3

1. The materials of scraper basket and rotary conveyor are stainless steel SS316L.

2. The material of the gasket is PTFE composite material(inner silicone, out layer PTFE)

3. The drive of the scraping film is magnetic coupling drive,the heating unit and the refrigeration unit are equipped with alternating current plug,the device is equipped with control box,the user has to provide 220V/ single - phase power supply.

4. The whole set of device will be assembled in advance in the factory of Dumasi instrument in Kunshan, Jiangsu. We will do the comprehensive inspections and tests. But for better transportation , the device will be modularized again.

5. All glass connections are processed through standard grinding.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Product Details Show

| Model | Hspd-60(b) | Hspd-80(b) | Hspd-100(b) | Hspd-150(b) | Hspd-200(b) | Hspd-230(b) |

| Effective Evaporation Area | 0.05 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Internal Condensation Area | 0.03 | 0.15 | 0.2 | 0.4 | 0.5 | 0.65 |

| Outer Condensing Area | 0.2 | 0.25 | 0.3 | 0.6 | 0.6 | 0.6 |

| Barrel Inside Diameter | 60 | 80 | 100 | 150 | 190 | 220 |

| Constant Pressure Feeding Funnel Volume | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Processing Flow | 0.1∽2.0 | 0.3∽4.0 | 0.5∽5.0 | 1.0∽8.0 | 1.5∽10.0 | 1.0∽15.0 |

| Motor Power | 120 | 120 | 120 | 120 | 200 | 200 |

| Max Rotation Speed | 450 | 450 | 450 | 450 | 450 | 450 |

Other general data

The materials of the feed tank,evaporator ,and the cold trap are all borosilicate 3.3

1. The materials of scraper basket and rotary conveyor are stainless steel SS316L.

2. The material of the gasket is PTFE composite material(inner silicone, out layer PTFE)

3. The drive of the scraping film is magnetic coupling drive,the heating unit and the refrigeration unit are equipped with alternating current plug,the device is equipped with control box,the user has to provide 220V/ single - phase power supply.

4. The whole set of device will be assembled in advance in the factory of Dumasi instrument in Kunshan, Jiangsu. We will do the comprehensive inspections and tests. But for better transportation , the device will be modularized again.

5. All glass connections are processed through standard grinding.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Device Parameters

|

Model

|

HRE-50

|

|

Rotary Flask (L)

|

50L

|

|

Collection Flask (L)

|

20L

|

|

Evaporating Speed(H2O)

|

>9L/h

|

|

Condenser Surface (㎡)

|

1.5

|

|

Condenser Pipe

|

Vertical, Main condenser+Vice condenser

|

|

Motor Power(W)

|

250W

|

|

Rotation Speed (rpm)

|

3~90rmp,Digital Display

|

|

Bath Power(KW)

|

6KW

|

|

Reachable Vacuum Rate

|

<133Pa (1.33mbar, 1 Torr)

|

|

Static Temp. Control Range& Wave(℃)

|

Water:RT-99 Oil:RT-180 ±0.2

|

|

Power

|

220V/50HZ, AC motor (ATEXOptional)

|

|

Glass Material

|

GG-17(3.3)High Borosilicate Glass

|

|

PTFE Sealing

|

Standard

|

|

PTFE Dump Valve

|

Standard

|

|

Vacuum Meter

|

Standard

|

|

Heating Bath

|

Stainless Steel,Hand-worked lift/Motor-driven lift

|

|

Bath Size(L*W*H)

|

1060*620*1200mm

|

Packing:

Our Service:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Certificate:

How To Contact Us:

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Application

| Flowers | Rose; jasmine; lavender; chamomile; ylang ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; honeysuckle; violets. |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedar wood; rosewood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine . |

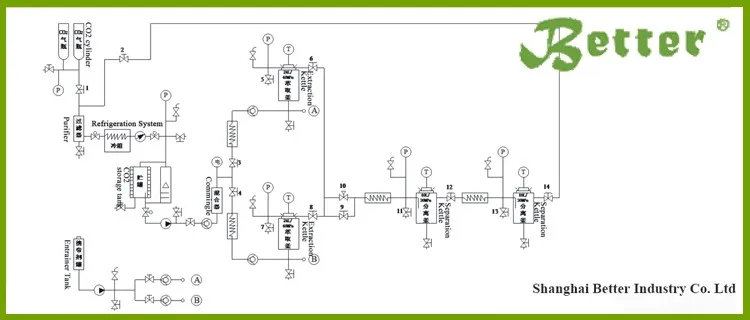

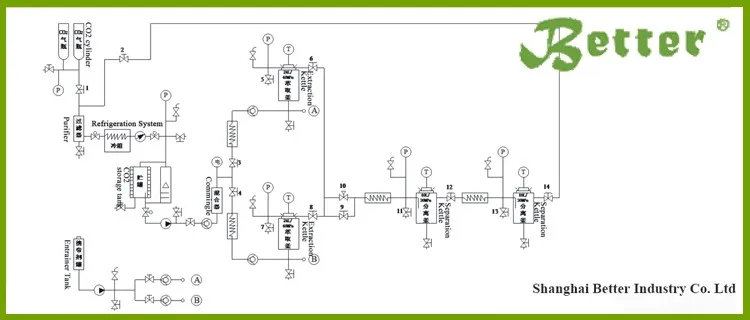

Sketch Of Flow Chart

Device Parameters

| Model | HEC10 | HEC20 | HEC30 | HEC50 | HEC100 | HEC150 | HEC200 | HEC300 |

| Voltage | 10V | 20V | 30V | 50V | 100V | 150V | 200V | 300V |

| Power | 4.0KW | 4.5KW | 5.5KW | 9KW | 12KW | 14KW | 25KW | 25KW |

| Specifications |

1. Steam extraction part is popular with the structure of basket-in-water 2. The operation part has adopted PLC or touch screen control system, this accords to customer’s demand. 3. This unit is automatically operate. 4. All kinds of plants can be the material of essential oil equipment. |

|||||||

1) Model: EC150 essential oil extration equipment

2) Power: 14KW (3 phase, 380v/50Hz)

3) Volume of distillation pot: 150L(according to demand of customers)

4) Heating area of distillation pot: 1.45M2

5) Condensation area of condenser: 1.25M2

6) Power of heater: 14KW

7) Size: 2000x900x2200mm (according to demand of customers)

Packing & Delivery

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Certificate

FAQ

What does Better need from me to quote a price?

a.Raw material; b.Production capacity per batch.

What is the oil yield?

The oil yield depends on the oil content of your material. If the oil content of your material is high, you can get more essential oil.

Can I use the machine to extract several kinds of raw materials?

Yes, of course.

Can I do the extraction test with my own raw material?

Yes, of course. We can do the extraction test and send you videos and test report for your Reference.

What heating way does your machine support?

Electricity/gas/wood/steam heating.

What is your material of your machine?

Stainless steel(Standard type is SUS304, it can be customized according to your request)

How long does it take to produce the machine once I place my order?

Usually, the delivery time is 30 working days after prepayment received.

What is the minimum quantity I must order?

We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.

Do you have machines in stock?

No, our machine is produced according to your request.

How will my order be packed, can you provide the installation service?

Packed in plywood case.

How To Contact Us:

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Introduction:

The Super Critical CO2 Herbal Extraction Machine is used for the extraction of material (solid or liquid)under high pressure and suitable temperature extraction.Changing conditions in the separation kettle, the dissolved substances will resolve in order to achieve the purpose of separation.Supercritical CO2 extraction equipment includes several parts: extraction kettle, separation kettle,mixer, CO2 high-pressure pump, co-solvent, refrigeration system, heat exchange system, CO2 storage tank, CO2 level gauge,purification system, flow meter, temperature control system, safety protection system etc.The supercritical CO2 extraction is specially suitable for extraction of fat-soluble and heat sensitive substances with high boiling point.Take CO2 as the solvent to make extraction and purification upon a lot of products such as biological products, foodstuff and medicines.

Features:

The supercritical units select the CO2 medium as the supercritical extraction agent, which makes it have the following characteristics: Wide operating range, easy to adjust Good selectivity, and through controlling the pressure and temperature, targeted extraction of the required ingredients Low operation temperature, the extraction is carried out at a temperature close to room temperature, which is particularly suitable for heat-sensitive components. The extraction process eliminates the possibility of oxidative and photoresponsive reactions, and the extract retains the natural flavor. Only one step from extraction to separation, the CO2 after extraction will not remain in the extracts CO2 is non-toxic, tasteless, non-flammable and easy to get and reused Fast extraction speed In recent years, supercritical extraction technology has got rapid development home and abroad, has realized the industrialized production in hops, spices, herbs, oils, petrochemicals, food health, and other areas.

1) Check power supply, electric wire to ensure intact. The power supply should be 3phase, 460V/60Hz. 2) Check refrigerator, ensure enough water in the water tank. 3) CO2 cylinder pressure not less than 5Mpa (Generally during 5-6Mpa). And CO2 cylinders should be full. 4) Check all pipeline joints and other joints. 5) Water tanks (for the heating jacket) should be fulfilled by water free of chloride/ Cl-. And tanks cannot be too full. The water level should be around 2cm distance to the cover of tanks. 6) The material kettle cannot be fulfilled too full. Raw material should be smashed into powder during 20-60mesh. If its size is less than 20mesh, it should be prilled no less than 20mesh. Also, its water content should be less than 10%. 7) Input material kettle into extraction kettle; input material kettle O-ring; input ventilation ring; install plunger; fasten clamps. 8) If co-solvent is used, add it through the co-solvent tank. Use the co-solvent pump.

Main Technical Param:

| The operation temperature scope | Room temperature ~75℃ |

| Designed pressure of extractor | 40Mpa |

| The max working pressure of extractor | 35Mpa |

| he volume of extractor | 50L*6 |

| Designed pressure of separator | 25Mpa |

| Max working pressure of separator | 20Mpa |

| First stage separator | 20L/25Mpa |

| Second stage separator | 20L/25Mpa |

| Purifying filter | 5L/16Mpa |

| Co-solvent flow | 0~20L/h |

| CO2 flow | 0~1000L/h |

| Cooling capacity | 25,000 Kcal/h |

| Required power supply | 3phase, 480V/60Hz |

| Rated power | 115kw, 250amps |

| Regular power consumption | around 60kw/h |

| Installation space (including operation space) | 8.0*9.0*4.5 (L*W*H by meter) |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What does BETTER need from me to quote a price?

a).Raw material

b).Production capacity per batch,we supply 0.5L~200L machine for you,big capacity of machine can be customized according to your request for your request.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5.Does the CO2 can be reused?

YES. CO2 can be used in circulation.

6.Does you machine can work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of the machine our customers. Every procedure and details have to be inspected strictly.

10. How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Winterization machine is used to refine the crude paste extracted by supercritical co2 extraction machine to get full spectrum crude oil.Winterization machine is whole system,it include mixing,winterization,filter and ethanol recovery part,the machine also can be equipped with de-pesticides&de-heavy metal part according to user’s requirements.Using winterization machine to refine crude paste will save much labor and time.

Continuous system,save much time and labor;

The capacity of ethanol recovery part is higher than normal ethanol recovery machine,the capacity of ethanol recovery part can be customized according to user’s requirements;

De-pesticides&De-heavy metal can be chosen as option;

Can be equipped with PLC controller;

Dimension of machine can be customized according to user’s warehouse

Packing:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

User Demand Analysis

Once the project is confirmed, the product level, processing technology and consulting group are analyzed according to the actual demands of customers so as to provide suitable engineering plans, form a complete production line and calculate the budget.

Engineering Design

We carry out planning and designs on details of engineering plans through introducing internationally advances design conception to provide valuable project technological plans and ensure effective implementation of all steps.

Product Manufacturing

The approved production drawing is the basis for production and manufacturing. All equipment that is not manufactured on the site shall be indentified by our quality responsible person so as to meet the strict stipulations.

Automatic Control Integration

The installation of the system and the whole automatic project meets the GMP standard and FDA standard. According to our years of experience, the installation and process rules will help simplify the starting and commissioning of equipment.

Trial Running and Training

During the equipment commissioning, our engineers will provide guidance on the site and carry out various tests with respect to all performances of the equipment with customers. Approval will be received from users.

Verification Services

To ensure normal production, we can set up maintenance and servicing plans for a single machine, the whole production line or the whole factory and provide equipment maintenance services and offer fittings according to customer requirements.

Q:What does BETTER need from me to quote a price?

1.Raw material

2.Production capacity per batch

Q:What is the oil yield?

The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.

Q:Can I use the machine to extract several kinds of raw materials?

Yes,of course.

Q:Can I do extraction test with my own raw material?

Yes,of course.We can do extraction test and send you videos and test report for your Reference.

Q:What heating way does your machine support?

Electricity/gas/wood/steam heating.

Q:What is your material of your machine?

Stainless steel(Standard type is SUS304,it can be customized according to your request)

Q:How long does it take to produce the machine once I place my order ?

Usually the delivery time is 30 working days after prepayment received.

Q:What is the minimum quantity I must order?

We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.

Q:Do you have machines in stock?

No,our machine is produced according to your request.

Q:How will my order be packed, can you provide the installation service?

Packed in plywood case.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

This Herb Solvent Extractor is suitable for medicine, health care products, bio-pharmaceuticals, cosmetics, food and other industries ambient pressure extraction, ultrasonic extraction, essential oils, aromatic oils Extraction, purification and other processes.This Herb Solvent Extractor is very suitable for universities, research institutes and enterprises, laboratories and pharmaceutical research and development departments of many varieties, small batch production use.

The Herb Solvent Extractor with high efficiency, this Herb Solvent Extractor is latest ultra-compact shaped ultrasonic dynamic extraction unit which developed by our company, this Herb Solvent Extractor optimize the product structure based on the traditional multi-extracting machines, extraction tanks, straight and helical cone conical extraction tank,integrated the Shaped ultrasonic device in this device, use the Ultrasonic dynamic loop extraction, extraction, filtration, concentrated under reduced pressure, oil condensate and other production processes to saving raw materials and working hours, work efficiency have been increased by 50% to 100% than the average multi-extraction equipment.

The Raw conversion rate is high, this Herb Solvent Extractor utilizes ultrasonic unique physical effects, cavitation can induce plant cell tissue broken or deformed, between solute particle vibration, shock acceleration, sound pressure shear stress strengthened, so that the material forming local points of extreme high temperature and pressure, to promote traditional Chinese medicine into the analysis of the effective , the extraction rate significantly increased up to 30-60% than the traditional process .

Herb Solvent Extractor is room temperature extraction, the active ingredient of the raw materials is not likely to lose. Meanwhile, BETTER series Herb Solvent Extractor uses a pneumatic agitation, enhanced ultrasound cavitation effect, so that medicines can be fully exposed to titanium ultrasonic probe, accelerated APIs homogeneous precipitation of the active ingredient inside.

Our Herb Solvent Extractor with the compact structure, fully exert the features of the Ultrasonic wave. The contact area of materials with ultrasonic is big, and the extraction time is short, ultrasonic herbal extracts are usually 20 to 40 minutes to get the best extraction rate, the extraction time is only 1/5 of the traditional pharmaceutical extraction process .

Shanghai BETTER Herb Solvent Extractor adaptability: it’s do not limited to ingredients polarity and molecular size for extract Chinese herbal. It’s applies to the extract of vast majority of Chinese herbal extracts and various ingredients;This ultrasonic machine is equipped with water separator and efficient condenser, aroma oils are vegetable oils can be extracted.

Equipment selectable frequency range:15KHz,20KHz,28 KHz,30 KHz,35 KHz,40 KHz,50 KHz,60 KHz,80KHz.

Vacuum concentration equipment: According to the raw materials of customer, the scraper concentrated material, l membrane concentration, falling film concentration, membrane concentration is optional.

|

Model |

HST |

|

Capacity |

20L---500L |

|

Maximum heating power |

Depending on the model, 5kw-30kw |

|

Mixing motor power |

Depending on the mode,75w-400kw |

|

High temperature magnetic pump power |

Depending on the mode,55w-200kw |

|

Ultrasonic Power |

Depending on the mode. 100w--3000kw |

|

Mixing control |

0-1500 rev / min, digital, stepless |

|

Temperature Control |

Temperature -65 °C, Configurable temperature, thermostat system |

|

Device Control |

Digital control machine/ PLC touch screen control |

|

Vacuum |

-0.05~ -0.08 |

|

Use solvent |

Water, ethanol, and petroleum ether |

|

Equipment Material |

SUS304/SUS316L |

|

Vacuum concentration system |

Vacuum concentration, condensation, cooling, water separator |

|

Material handling capacity |

Depending on the model, 1.2 - 300 kg / hr range |

|

Dimension |

1600mm*850mm*1800mm |

Packing:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

User Demand Analysis

Once the project is confirmed, the product level, processing technology and consulting group are analyzed according to the actual demands of customers so as to provide suitable engineering plans, form a complete production line and calculate the budget.

Engineering Design

We carry out planning and designs on details of engineering plans through introducing internationally advances design conception to provide valuable project technological plans and ensure effective implementation of all steps.

Product Manufacturing

The approved production drawing is the basis for production and manufacturing. All equipment that is not manufactured on the site shall be indentified by our quality responsible person so as to meet the strict stipulations.

Automatic Control Integration

The installation of the system and the whole automatic project meets the GMP standard and FDA standard. According to our years of experience, the installation and process rules will help simplify the starting and commissioning of equipment.

Trial Running and Training

During the equipment commissioning, our engineers will provide guidance on the site and carry out various tests with respect to all performances of the equipment with customers. Approval will be received from users.

Verification Services

To ensure normal production, we can set up maintenance and servicing plans for a single machine, the whole production line or the whole factory and provide equipment maintenance services and offer fittings according to customer requirements.

Q:What does BETTER need from me to quote a price?

1.Raw material

2.Production capacity per batch

Q:What is the oil yield?

The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.

Q:Can I use the machine to extract several kinds of raw materials?

Yes,of course.

Q:Can I do extraction test with my own raw material?

Yes,of course.We can do extraction test and send you videos and test report for your Reference.

Q:What heating way does your machine support?

Electricity/gas/wood/steam heating.

Q:What is your material of your machine?

Stainless steel(Standard type is SUS304,it can be customized according to your request)

Q:How long does it take to produce the machine once I place my order ?

Usually the delivery time is 30 working days after prepayment received.

Q:What is the minimum quantity I must order?

We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.

Q:Do you have machines in stock?

No,our machine is produced according to your request.

Q:How will my order be packed, can you provide the installation service?

Packed in plywood case.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

This Low Temperature Ethanol Extraction Machine is applicable for the multiple technology of normal pressure ,micro pressure,water frying ,warm soaking ,thermal reflux,compulsory circulation,filtration,redolent oil extraction and organically solvent recycling in traditional Chinese medicine,food and chemical industry. It is equipped with CIP cleaning device in the tank. solvent extraction

1. TheLow Temperature Ethanol Extraction Machine consists of extractor, tubular heater, evaporator, condenser, oil-liquid separator, oil collector, medicine liquid pump, weighing vent, liquid storage tank, filter, vacuum pump, and electric cabinet. Defoamers are fixed in the steam outlet of the extractor and evaporator. The units without steam heating can be fixed with oil heating system.

2. It can be operate to hot recyling distill and condense, normal extraction, concentration, precipitation and percolation.

3. It can work in the condition of negative pressure, atm. and positive pressure. It can apply to distill water, ethanol and solvent, up to GMP standard.

4. The Low Temperature Ethanol Extraction Machine has great advantages in multi-function, high efficiency, energy saving, and wide operation arrange. It pioneers in comprehensive capacity in nationwide; it is the pilot equipment in distilling natural herbal medicine, especially fit for research institution, universities and collages, and factory pilot experiment, or distilling valued medicine, or low temperature fresh herbal. It has been widely used in factories.

| Model | Capacity | Hot water generator power | Material | Heating Area of Extraction Tank | Condensing Area of Condenser | Vacuum pump power |

| HST10 | 10L | 6KW | SUS304/316 | 0.21M2 | 0.22 M2 | 0.55KW |

| HST20 | 20L | 8.8KW | SUS304/316 | 0.28 M2 | 0.5 M2 | 0.55KW |

| HST30 | 30L | 10KW | SUS304/316 | 0.33 M2 | 0.72 M2 | 1.5 KW |

| HST50 | 50L | 12KW | SUS304/316 | 0.5 M2 | 0.83 M2 | 3KW |

| HST100 | 100L | 24KW | SUS304/316 | 0.98 M2 | 0.95 M2 | 4KW |

| HST150 | 150L | 25KW | SUS304/316 | 1.45 M2 | 1.2 M2 | 4KW |

| HST200 | 200L | 27KW | SUS304/316 | 1.85 M2 | 1.5 M2 | 6.5 KW |

| HST300 | 300L | 35KW | SUS304/316 | 2.85 M2 | 2.3 M2 | 8KW |

|

Pharmaceutical |

analytical solution of antibiotic resin for desalination and concentration, vitamin concentration |

||

|

Dye |

desalination and concentration, instead of salting out, acid |

||

|

Amino acid |

decolorization, impurity removal, concentration and desalination |

||

|

Food |

oligosaccharides, starch, sugar, separation, purification, fruit juice concentrate, plant extract |

||

|

Recovery of mother liquor |

MSG mother liquor purification, glucose crystallization solution impurity etc. |

||

|

Water treatment |

printing and dyeing waste-water treatment, water reuse, ultra pure water preparation |

||

|

Acid, alkali recovery |

pharmaceutical industry washing column acid, alkali waste liquid, chemical fiber industry waste acid, alkali |

||

Packing:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

User Demand Analysis

Once the project is confirmed, the product level, processing technology and consulting group are analyzed according to the actual demands of customers so as to provide suitable engineering plans, form a complete production line and calculate the budget.

Engineering Design

We carry out planning and designs on details of engineering plans through introducing internationally advances design conception to provide valuable project technological plans and ensure effective implementation of all steps.

Product Manufacturing

The approved production drawing is the basis for production and manufacturing. All equipment that is not manufactured on the site shall be indentified by our quality responsible person so as to meet the strict stipulations.

Automatic Control Integration

The installation of the system and the whole automatic project meets the GMP standard and FDA standard. According to our years of experience, the installation and process rules will help simplify the starting and commissioning of equipment.

Trial Running and Training

During the equipment commissioning, our engineers will provide guidance on the site and carry out various tests with respect to all performances of the equipment with customers. Approval will be received from users.

Verification Services

To ensure normal production, we can set up maintenance and servicing plans for a single machine, the whole production line or the whole factory and provide equipment maintenance services and offer fittings according to customer requirements.

Q:What does BETTER need from me to quote a price?

1.Raw material

2.Production capacity per batch

Q:What is the oil yield?

The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.

Q:Can I use the machine to extract several kinds of raw materials?

Yes,of course.

Q:Can I do extraction test with my own raw material?

Yes,of course.We can do extraction test and send you videos and test report for your Reference.

Q:What heating way does your machine support?

Electricity/gas/wood/steam heating.

Q:What is your material of your machine?

Stainless steel(Standard type is SUS304,it can be customized according to your request)

Q:How long does it take to produce the machine once I place my order ?

Usually the delivery time is 30 working days after prepayment received.

Q:What is the minimum quantity I must order?

We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.

Q:Do you have machines in stock?

No,our machine is produced according to your request.

Q:How will my order be packed, can you provide the installation service?

Packed in plywood case.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Supercritical CO2 extraction technology is the latest subject in modern chemical separation and it is an advanced separation technology rising in the world. The so-called supercritical fluid is the thermodynamic state liquid which is above the critical point and the critical point is the point at which the gas-liquid interface just disappears. The supercritical fluid has a very unique physical and chemical properties, its density close to the liquid, viscosity close to the gas.The big diffusion coefficient, low viscosity, big dielectric constant and other characteristics make its separation effect better, so it is a good solvent. Supercritical extraction, namely, under high pressure and appropriate temperature, solvent contact with the material in the extraction vessel, the solute diffuses into the solvent, and then in the separator change the operating conditions to separate out the dissolved substance in order to achieve separation purposes.

The supercritical units select the CO2 medium as the supercritical extraction agent, which makes it have the following characteristics:

Wide operating range, easy to adjust;

Good selectivity, and through controlling the pressure and temperature, targeted extraction of the required ingredients;

Low operation temperature, the extraction is carried out at a temperature close to room temperature, which is particularly suitable for heat-sensitive components. The extraction process eliminates the possibility of oxidative and photoresponsive reactions, and the extract retains the natural flavor;

Only one step from extraction to separation, the CO2 after extraction will not remain in the extracts;

CO2 is non-toxic, tasteless, non-flammable and easy to get and reused;

Fast extraction speed;

In recent years, supercritical extraction technology has got rapid development home and abroad, has realized the industrialized production in hops, spices, herbs, oils, petrochemicals, food health, and other areas.

| APPLICATION | Supercritical CO2 Oil Extraction Machine/Equipment |

| Agriculture Food | Extraction of pesticides and soil contaminants. Separation of fats and contaminats, flavors. |

| Pharmaceutical | Extraction of active components, preparation of natual products, viamins. |

| Cosmetic | Extraction of fragrances and oils. |

| Laundry | Dry cleaning of garments. |

| Mechanical | Degreasing parts, precision cleaning of high-value components. |

| A wide range of industries for the extraction of natural products for the food additives(such as ginger, large bolt, cinnamon, anise, hops, pepper, cumin,etc.), drugs(such as Artemisia annua vegetarian, magnolia, Angelia, etc.), health care(such as sea buckthorn, samara, pomegranate, lycopene, etc.) | |

1.The air source part

CO2 gas cylinders (provided by customer), the cylinder pressure generally remain at more than 5 mpa, CO2 purity of 99.99% or higher

2.Cooling part

Refrigeration parts by enclosed refrigeration compressor, storage tank, cold box, temperature controller with spiral coil and tube valve parts, imported compressor.

Cold box is equipped with refrigeration temperature automatic control system and can be arbitrarily set refrigeration required temperature, cold box into the tank, insulation, CO2 coil and stainless steel decorative layer.

Storage tank: 10L/ 16 mpa for liquid CO2 storage.

3.Power supply part

CO2 high-pressure plunger pump:one set

power 2.2 kw, maximum flow is 50L/h, maximum working pressure of 40 mpa.

Carrying agent pump: the maximum flow 10L/h, maximum working pressure of 40 mpa.

4.Purifying filtration system

16 mpa design pressure, volume 1L, the quantity is 1 only, built-in silica gel or other used to filter material, have the effect of filtering, can be put into use in parallel.

5.The extraction kettle

Volume is 5L, the highest working pressure of 40 mpa, maximum operating temperature 80 ℃, two extraction kettle can be used in parallel, with solid material inside the basket (1 in 1 case), material basket of split up and down, convenient discharging, used for extraction of solid material; The heating jacket and insulation kettle body, and is equipped with stainless steel decorative layer. Extraction kettle seal with special structure and special sealing material, structure for sealing, the higher the pressure, the better the self-styled, and fast to open, use for a long time do not need to replace the sealing ring.

6.Separate kettle

Two sets of separate kettle to 2 liters, the highest working pressure are 20 mpa, entrance to be close to the bottom, intubation set heating jacket and insulation kettle in vitro, maximum separation temperature up to 80 ℃.

7.Preheater: the highest working pressure of 40 mpa, the maximum operating temperature 80 ℃, preheater under constant temperature water bath, the water tank with insulation layer, and is equipped with stainless steel decorative layer. Preheater with constant temperature water bath as a whole, reduce the water hot water transmission, and make corresponding preheater with every body temperature more step convergence, more compact structure.

8. Thermodynamic cycle using corrosion and heat-resistant pipeline pump, number 3 only.

9.Flowmeter: metal tube flow meter with secondary instrument, it can display instantaneous flow, and cumulative flow can be shown, it is mainly used for measuring CO2 flow volume.

10.Heating control system

The system is to use temperature controller to set the required temperature, the heat resistance temperature measurement, the feedback signal to the temperature controller, in order to achieve the purpose of temperature control. The extraction kettle, the separator adopts the temperature control of temperature controller.

11.All with vibration-proof pressure gauge pressure gauges.

12. Safety protection device

The device is equipped with electrode point pressure gauge, over-voltage protection, when the pressure rose to the point of electrode pressure gauge set, the control system will automatically cut off the pump power supply, pump stop working, and make the pressure does not exceed the set pressure. In addition, the extraction kettle, separate kettle are equipped with safety valve, when pressure exceeds the pressure of the relief valve set, relief valve on the overflow, the pressure drop and the implementation of pressure protection.

13. Manual and automatic extraction part pressure feedback control:

The distinctive features of the device is in extraction parts both manual voltage regulator, and automatic pressure control section, the manual and automatic dissolve into an organic whole, make the pressure greatly improve the accuracy of setting control, control accuracy can reach 0.5%, the purity of the extracted components is higher.

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil, etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5. Can the CO2 be reused?

YES. CO2 can be used in circulation.

6. Can your machine work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

This system is multi-function SPE equipment, the working mode is intermittent or continuous way to extract solvent from solid or liquid material, the additive can be add to the supercritical fluid;

The system has one extractor and two separators;

The highest working pressure of solid extractor is 50Mpa, the highest working temperature is 85°C;

The design of pressure vessels according the related national standard and rule demand and with over pressure protection system which means enough safety valve;

The whole equipment beauty, safety and easy operation, pressure temperature flow number can be showed from pressure meter and digital instrument. The material of pipe parts, valves, pipe lines, are all stainless steel(0Cr18Ni9Ti).

Neem Oil Extraction Machine is a kind of green separation technology which separating solute from solid or liquid material by using supercritical fluid solvent.

Neem Oil Extraction Machine is a perfect solvent:

1)it has good permeabilityand low viscosity as gas;

2) it has close density and fine solution capacity as liquid;

3)solution capacity depend on the density, pressure and temperature of solvent.

So the principle of SCFE is by changing the density, pressure and temperature of CO2 solvent to extract different solute from solid or liquid material.

| APPLICATION | Supercritical CO2 Oil Extraction Machine/Equipment |

| Agriculture Food | Extraction of pesticides and soil contaminants. Separation of fats and contaminats, flavors. |

| Pharmaceutical | Extraction of active components, preparation of natual products, viamins. |

| Cosmetic | Extraction of fragrances and oils. |

| Laundry | Dry cleaning of garments. |

| Mechanical | Degreasing parts, precision cleaning of high-value components. |

| A wide range of industries for the extraction of natural products for the food additives(such as ginger, large bolt, cinnamon, anise, hops, pepper, cumin,etc.), drugs(such as Artemisia annua vegetarian, magnolia, Angelia, etc.), health care(such as sea buckthorn, samara, pomegranate, lycopene, etc.) | |

Small size supercritical device

| Type | Power(KW) | Design Pressure(Mpa) | Design Temperature(°c) | Floor Area(m²) | Height(m) |

| 0.5L | 5 | 50 | Home temperature ˜ 85°c | 1.5 | 1.8 |

| 1L | 8 | 2 | 1.8 | ||

| 5L | 16 | 4 | 1.8 | ||

| 10L | 25 | 8 | 2 | ||

| 20L | 40 | 40 | 10 | 4 | |

| 24L | 40 | 10 | 4 | ||

| 24L*2 | 45 | 12 | 4 | ||

| 25L*4 | 60 | 15 | 4 | ||

| Description |

1.All the types have two separators; |

||||

| Type | Design Pressure(Mpa) | Design Temperature(°c) | Design Flow(L/H) | Floor Area(m²) | Height(m) |

| 50L*3 | 35-55 | 60-90 | 600 | ≤80 | ≤6 |

| 100L*3 | 1000 | ≤130 | ≤7 | ||

| 200L*3 | 1500 | ≤200 | ≤9 | ||

| 300L*3 | 2500 | ≤250 | ≤9 | ||

| Description | All the types are 3 extract and 2 separate system, don’t contain countercurrent extraction and extraction tower, All purchased part are famous brands home and abroad, pressure vessels contacting with CO2 is packing up structure, the material of inner is 304 stainless steel, PLC auto and manual double control system, with tail-gas recover system and electro-heating system. | ||||

| More than 400L*3 can be customized | |||||

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil, etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5. Can the CO2 be reused?

YES. CO2 can be used in circulation.

6. Can your machine work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +86-2160518061,+86-2160519925

Mobile/whatsapp: +86-18917686969

Skype: joyceleejoe

Email: info@better-industry.com

Address: Bldg. 80, Liandong Ugu, Jiading District, Shanghai, China