Supercritical CO2 extraction technology is the latest subject in modern chemical separation and it is an advanced separation technology rising in the world. The so-called supercritical fluid is the thermodynamic state liquid which is above the critical point and the critical point is the point at which the gas-liquid interface just disappears. The supercritical fluid has a very unique physical and chemical properties, its density close to the liquid, viscosity close to the gas.The big diffusion coefficient, low viscosity, big dielectric constant and other characteristics make its separation effect better, so it is a good solvent. Supercritical extraction, namely, under high pressure and appropriate temperature, solvent contact with the material in the extraction vessel, the solute diffuses into the solvent, and then in the separator change the operating conditions to separate out the dissolved substance in order to achieve separation purposes.

The supercritical units select the CO2 medium as the supercritical extraction agent, which makes it have the following characteristics:

Wide operating range, easy to adjust;

Good selectivity, and through controlling the pressure and temperature, targeted extraction of the required ingredients;

Low operation temperature, the extraction is carried out at a temperature close to room temperature, which is particularly suitable for heat-sensitive components. The extraction process eliminates the possibility of oxidative and photoresponsive reactions, and the extract retains the natural flavor;

Only one step from extraction to separation, the CO2 after extraction will not remain in the extracts;

CO2 is non-toxic, tasteless, non-flammable and easy to get and reused;

Fast extraction speed;

In recent years, supercritical extraction technology has got rapid development home and abroad, has realized the industrialized production in hops, spices, herbs, oils, petrochemicals, food health, and other areas.

| APPLICATION | Supercritical CO2 Oil Extraction Machine/Equipment |

| Agriculture Food | Extraction of pesticides and soil contaminants. Separation of fats and contaminats, flavors. |

| Pharmaceutical | Extraction of active components, preparation of natual products, viamins. |

| Cosmetic | Extraction of fragrances and oils. |

| Laundry | Dry cleaning of garments. |

| Mechanical | Degreasing parts, precision cleaning of high-value components. |

| A wide range of industries for the extraction of natural products for the food additives(such as ginger, large bolt, cinnamon, anise, hops, pepper, cumin,etc.), drugs(such as Artemisia annua vegetarian, magnolia, Angelia, etc.), health care(such as sea buckthorn, samara, pomegranate, lycopene, etc.) | |

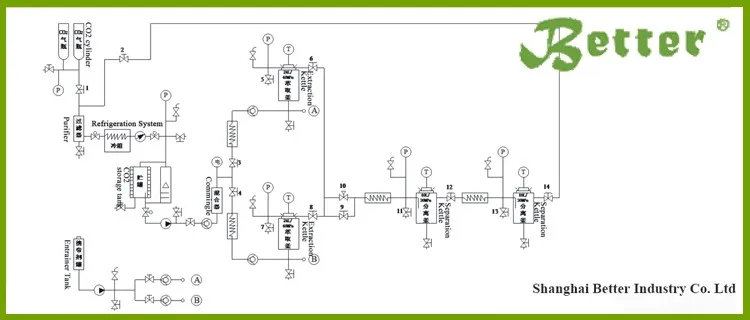

1.The air source part

CO2 gas cylinders (provided by customer), the cylinder pressure generally remain at more than 5 mpa, CO2 purity of 99.99% or higher

2.Cooling part

Refrigeration parts by enclosed refrigeration compressor, storage tank, cold box, temperature controller with spiral coil and tube valve parts, imported compressor.

Cold box is equipped with refrigeration temperature automatic control system and can be arbitrarily set refrigeration required temperature, cold box into the tank, insulation, CO2 coil and stainless steel decorative layer.

Storage tank: 10L/ 16 mpa for liquid CO2 storage.

3.Power supply part

CO2 high-pressure plunger pump:one set

power 2.2 kw, maximum flow is 50L/h, maximum working pressure of 40 mpa.

Carrying agent pump: the maximum flow 10L/h, maximum working pressure of 40 mpa.

4.Purifying filtration system

16 mpa design pressure, volume 1L, the quantity is 1 only, built-in silica gel or other used to filter material, have the effect of filtering, can be put into use in parallel.

5.The extraction kettle

Volume is 5L, the highest working pressure of 40 mpa, maximum operating temperature 80 ℃, two extraction kettle can be used in parallel, with solid material inside the basket (1 in 1 case), material basket of split up and down, convenient discharging, used for extraction of solid material; The heating jacket and insulation kettle body, and is equipped with stainless steel decorative layer. Extraction kettle seal with special structure and special sealing material, structure for sealing, the higher the pressure, the better the self-styled, and fast to open, use for a long time do not need to replace the sealing ring.

6.Separate kettle

Two sets of separate kettle to 2 liters, the highest working pressure are 20 mpa, entrance to be close to the bottom, intubation set heating jacket and insulation kettle in vitro, maximum separation temperature up to 80 ℃.

7.Preheater: the highest working pressure of 40 mpa, the maximum operating temperature 80 ℃, preheater under constant temperature water bath, the water tank with insulation layer, and is equipped with stainless steel decorative layer. Preheater with constant temperature water bath as a whole, reduce the water hot water transmission, and make corresponding preheater with every body temperature more step convergence, more compact structure.

8. Thermodynamic cycle using corrosion and heat-resistant pipeline pump, number 3 only.

9.Flowmeter: metal tube flow meter with secondary instrument, it can display instantaneous flow, and cumulative flow can be shown, it is mainly used for measuring CO2 flow volume.

10.Heating control system

The system is to use temperature controller to set the required temperature, the heat resistance temperature measurement, the feedback signal to the temperature controller, in order to achieve the purpose of temperature control. The extraction kettle, the separator adopts the temperature control of temperature controller.

11.All with vibration-proof pressure gauge pressure gauges.

12. Safety protection device

The device is equipped with electrode point pressure gauge, over-voltage protection, when the pressure rose to the point of electrode pressure gauge set, the control system will automatically cut off the pump power supply, pump stop working, and make the pressure does not exceed the set pressure. In addition, the extraction kettle, separate kettle are equipped with safety valve, when pressure exceeds the pressure of the relief valve set, relief valve on the overflow, the pressure drop and the implementation of pressure protection.

13. Manual and automatic extraction part pressure feedback control:

The distinctive features of the device is in extraction parts both manual voltage regulator, and automatic pressure control section, the manual and automatic dissolve into an organic whole, make the pressure greatly improve the accuracy of setting control, control accuracy can reach 0.5%, the purity of the extracted components is higher.

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil, etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5. Can the CO2 be reused?

YES. CO2 can be used in circulation.

6. Can your machine work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

English

English