The Supercritical CO2 Oil Extraction Machine/Equipment is suitable for producing pharmaceutical CBD and various essential oil and hemp oil extraction, herbal and plant oil extraction. It is widely used to produce garlic oil, essential oil, rose oil, caffeine, fructus hippophae, etc.

| APPLICATION | Supercritical CO2 Oil Extraction Machine/Equipment |

| Agriculture Food | Extraction of pesticides and soil contaminants. Separation of fats and contaminats, flavors. |

| Pharmaceutical | Extraction of active components, preparation of natual products, viamins. |

| Cosmetic | Extraction of fragrances and oils. |

| Laundry | Dry cleaning of garments. |

| Mechanical | Degreasing parts, precision cleaning of high-value components. |

| A wide range of industries for the extraction of natural products for the food additives(such as ginger, large bolt, cinnamon, anise, hops, pepper, cumin,etc.), drugs(such as Artemisia annua vegetarian, magnolia, Angelia, etc.), health care(such as sea buckthorn, samara, pomegranate, lycopene, etc.) | |

| SPECIFICATIONS | |||||||

| No. | Model | Capacity | Pressure(Mpa) | Temperature(℃) | Power(KW) | CO2 Pump Flow(L/H) | Dimension(mm) |

| 1 | HSFE0.5 | 0.5L*1 | 50 | 85 | 10 | 50 | 2500*2500*1600 |

| 2 | HSFE1 | 1L*1 | 10 | 50 | 2500*2500*1600 | ||

| 3 | HSFE5 | 5L*1 | 18 | 50 | 2500*2500*1600 | ||

| 4 | HSFE10 | 10L*1 | 40 | 18 | 100 | 3000*2500*1600 | |

| 5L*2 | |||||||

| 5 | HSFE20 | 10L*2 | 25 | 200 | 3000*3000*1800 | ||

| 6 | HSFE30 | 10L*3 | 30 | 210 | 5000*4800*1800 | ||

| 7 | HSFE48 | 24L*2 | 45 | 400 | 5000*5000*4200 | ||

| 8 | HSFE96 | 24L*4 | 58 | 600 | 5800*5000*4200 | ||

| 9 | HSFE100 | 50L*2 | 60 | 800 | 6200*6000*4500 | ||

| 10 | HSFE120 | 30L*4 | 60 | 800 | 6800*6000*4500 | ||

| 11 | HSFE150 | 50L*3 | 63 | 1000 | 7200*6000*4500 | ||

| 12 | HSFE200 | 50L*4 | 65 | 1000 | 7800*7000*4500 | ||

| For capacity above 200L, it will be custom made. | |||||||

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil, etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5. Can the CO2 be reused?

YES. CO2 can be used in circulation.

6. Can your machine work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

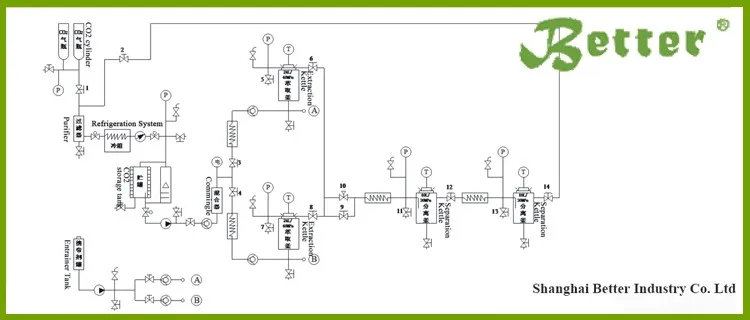

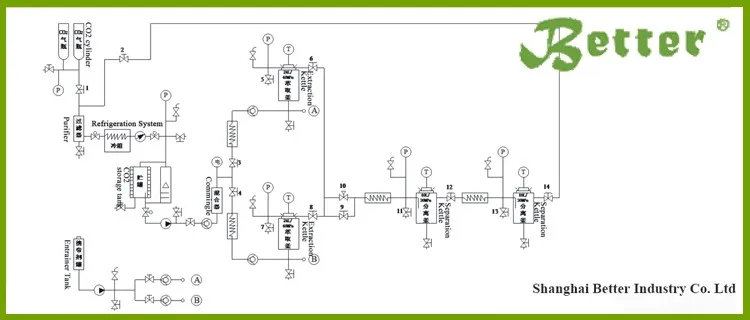

The device is used for the extraction of material (solid or liquid)under high pressure and suitable temperature extraction. Changing conditions in the separation kettle, the dissolved substances will resolve in order to achieve the purpose of separation. Supercritical CO2 extraction equipment includes several parts: extraction kettle, separation kettle, commingle, CO2 high-pressure pump, entrainer pump, refrigeration system, heat exchange system, CO2 storage tank, CO2 level gauge,purification system, flow meter, temperature control system, safety protection system etc.The supercritical CO2 extraction is especially suitable for extraction of fat-soluble and heat-sensitive substances with high boiling point. Take CO2 as the solvent to make extraction and purification upon a lot of products such as biological products, foodstuff, and medicines.

1) Intermittent or continuous work,co-solvent can be added if a request

2) CO2 can be recovered and reused;

3) Pressure and temperature can be designed according to demand.

4) Can custom made into PLC or computer control

| SPECIFICATIONS | |||||||

| No. | Model | Capacity | Pressure(Mpa) | Temperature(℃) | Power(KW) | CO2 Pump Flow(L/H) | Dimension(mm) |

| 1 | HSFE0.5 | 0.5L*1 | 50 | 85 | 10 | 50 | 2500*2500*1600 |

| 2 | HSFE1 | 1L*1 | 10 | 50 | 2500*2500*1600 | ||

| 3 | HSFE5 | 5L*1 | 18 | 50 | 2500*2500*1600 | ||

| 4 | HSFE10 | 10L*1 | 40 | 18 | 100 | 3000*2500*1600 | |

| 5L*2 | |||||||

| 5 | HSFE20 | 10L*2 | 25 | 200 | 3000*3000*1800 | ||

| 6 | HSFE30 | 10L*3 | 30 | 210 | 5000*4800*1800 | ||

| 7 | HSFE48 | 24L*2 | 45 | 400 | 5000*5000*4200 | ||

| 8 | HSFE96 | 24L*4 | 58 | 600 | 5800*5000*4200 | ||

| 9 | HSFE100 | 50L*2 | 60 | 800 | 6200*6000*4500 | ||

| 10 | HSFE120 | 30L*4 | 60 | 800 | 6800*6000*4500 | ||

| 11 | HSFE150 | 50L*3 | 63 | 1000 | 7200*6000*4500 | ||

| 12 | HSFE200 | 50L*4 | 65 | 1000 | 7800*7000*4500 | ||

| For capacity above 200L, it will be custom made. | |||||||

Packing & Delivery:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

a).Raw material

b). Production capacity per batch,we supply 0.5L~200L machine for you,big capacity of machine can be customized according to your request for your request.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil, etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5. Can the CO2 be reused?

YES. CO2 can be used in circulation.

6. Can your machine work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of machine our customers. Every procedure and details have to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Essential oil vacuum distillation

1.Model of essential oil extract equipment:

| Model | HEC10 | HEC20 | HEC30 | HEC50 | HEC100 | HEC150 | HEC200 | HEC300 |

| Voltage | 10V | 20V | 30V | 50V | 100V | 150V | 200V | 300V |

| Power | 4.0KW | 4.5KW | 5.5KW | 9KW | 12KW | 14KW | 25KW | 25KW |

| Specifications |

1. Steam extraction part is popular with the structure of basket-in-water 2. Operation part has adopted PLC or touch screen control system, this accords to customer’s demand. 3. This unit is automatically operate. 4. All kinds of plants can be the material ofessential oil equipment . |

|||||||

2.Specifications of essential oil extract equipment:

1. Power: 14kw, 380v/50Hz, Three Phases

2. Volume of Distillation Pot: 150L

3. Moisture Extraction Temperature: 100c

4. Volume of Extraction Tank: 150L

5. Cooling From Tap Water or cooling machine

6. Material: SUS304 2B

7. Size: 2000x900x2200mm (According to customer’s demand)

3.Features of essential oil extract equipment:

1. This essential oil equipment is by steam-distillation to reach the extraction of essential oils.

2. Easy operation. One people can operate this rose oil extraction equipment easily .

3. High efficiency. This essential oil equipment can quickly reach 100°C high temperature under the conditions of cleanness, safety and atmospheric pressure. If required, with vacuum pump, the extraction speed of essential oils will be more faster.

4. Compact structure. It covers only about 1.5 square meter.

4.Technical datas EC150 essential oil extract equipment:

1) Model: EC150 essential oil extration equipment

2) Power: 14KW (3 phase, 380v/50Hz)

3) Volume of distillation pot: 150L(according to demand of customers)

4) Heating area of distillation pot: 1.45M2

5) Condensation area of condenser: 1.25M2

6) Power of heater: 14KW

7) Size: 2000x900x2200mm (according to demand of customers)

6.Pictures of essential oil extract equipment:

Drawing of Essential oil extract equipment

Structure of essential oil extract machine

Heating control part of Essential oil extract machine

Material of Essential oil extrat equipment:

Wood power of essential oil extract machine

Oil-water separation part of essential oil extract equipment

Essential oil:

Final product of essential oil:

Package of Essential oil extraction equipment

Thank you for browsing essential oil extract equipment 150L !

Belt dryer is widely-used continuous drying equipment, which is consisted of feeding device, one or several drying chambers. Raw material is spread on belt conveyor and hot air will pass through the raw materials from up to lower or bottom-up. In this way the raw material can be dried uniformly. Each chamber is equipped with main chamber, drive system, heating system, hot air recycle fan, and dehumidifying system. According to abundant experiences and new technology, we improved the traditional belt dryer to meet the GMP standard and meet the requirements of different raw materials.

The hot air goes through the material from up to lower or bottom-up, with high speed, high pressure and even distribution, the contacting area between the material and hot air is enlarged, and the drying speed gets improved. The heat source is gas indirect furnace. The hot air box is below the recycle fan. There are hot air distributing pipe outside the chamber, so that the hot air can sprayed evenly from the retaining plate, the advantages of this structure are: The drying temp is easy to be controlled, which is significant for various material drying process; The hot air is sprayed through retaining plate, which made the temperature evenly and can avoid partial high temperature No maintenance for hot air box, the hot air box is inner set and outside preservation, which can minimize heat loss There are air filter for the exhaust fan, frequently cleaning can avoid miscellany and pollution. The dehumidifying fan is above the feeding device, which is used for discharging the used high-moisture and low-temp air. The hot air is recycling from discharging section to feeding section, so as to save energy effectively. The whole equipment is full weld to avoid wind channeling. There is no leaking during cleaning, which can ensure the quality of final product. Fully-closed model is available, to make sure that the product will not be polluted and heat is high efficient. The access door makes the maintain and cleaning work convenient The DW is a energy-saving belt dryer. The air distribution is more even, hot air speed is higher, penetrating is effective, drying is more strength. This system is inner recycle type; primary selection is DW3-2-25, including 12 drying units, for each section, there is thermal resistance automatic control independent and with digital show. All key components are provided by famous manufacturer, which can ensure long-term operation of the equipment. The belt speed can be electromagnetic adjusted, and the adjust range is large, besides, the speed can be directly displayed on the control cabinet screen, so that the final moisture can be controlled effectively. Primary and Middle Filter can ensure the clean air inlet All recycle fans are centrifugal, which are low consumption, high pressure and high penetration rate.

| Name | SPEC | Material | QTY |

| Mainframe System | |||

| frame | 60×80 | Carbon steel | 1set |

| Mainframe | DW3-1.5×25 | SUS304 belt | 1set |

| Insulation thickness | 60mm | Glass wool | 1set |

| Dehumidify fan | 4-72-6A4.0kW | C.S | 12pc |

| Circulating fan | 4-72-5A2.2kW | C.S | 5pc |

| Reduction gears of belt | 0.75 kW | assembly | 2pc |

| Transmission shaft | 45# | 6pc | |

| Belt chain wheel | Z=10,P=76.2 | 45# | 12pc |

| Link chain | P=76.2 | Carbon steel | 300m |

| Belt | 8 mesh | SUS304 | 157m |

| Striker plate | H100mm, δ1.2 | SUS304 | 3950 |

| Belt stay bar | Out 23, in15 | Zinc coat | 990 |

| Belt, chain, wheel | Carbon steel | Zinc coat | 3 set |

| mounted bearings | UCK210 | assembly | 12set |

| Gate lock door hinge | assembly | Whole set | |

| Sealing strip | E | Silicon rubber | |

| thermal resistance | Pt100 | assembly | 18set |

| Belt tighten device | Carbon steel | 6set | |

| Dehumidify duct | Zinc coat | 5set | |

| Inlet air duct | Zinc coat | 1 set | |

| Heating System | |||

| burner | RS100 | 1 set | |

| Gas fuel furnace | 100×104kcal/h | Inside SUS304 | 1 set |

| Air blower | 4-72-8C-30kW | ||

| Control System | |||

| Control cabinet | button | 1 set | |

| Electrical element | 1 set | ||

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q: What does Better need from me to quote a price?

1.Raw material

2.Production capacity per batch

Q: How long does it take to produce the machine once I place my order?

Usually, the delivery time is 30 working days after prepayment received.

Q: What is the minimum quantity I must order?

We don't technically have minimums, but if you order more than 3 sets once,we can give you a discount.

Q: Do you have machines in stock?

No, our machine is produced according to your request.

Q: How will my order be packed, can you provide the installation service?

Packed in plywood case.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Supercritical CO2 extraction technology is the latest subject in modern chemical separation and it is an advanced separation technology rising in the world. The so-called supercritical fluid is the thermodynamic state liquid which is above the critical point and the critical point is the point at which the gas-liquid interface just disappears. The supercritical fluid has a very unique physical and chemical properties, its density close to the liquid, viscosity close to the gas.The big diffusion coefficient, low viscosity, big dielectric constant and other characteristics make its separation effect better, so it is a good solvent. Supercritical extraction, namely, under high pressure and appropriate temperature, solvent contact with the material in the extraction vessel, the solute diffuses into the solvent, and then in the separator change the operating conditions to separate out the dissolved substance in order to achieve separation purposes.

The supercritical units select the CO2 medium as the supercritical extraction agent, which makes it have the following characteristics: Wide operating range, easy to adjust Good selectivity, and through controlling the pressure and temperature, targeted extraction of the required ingredients Low operation temperature, the extraction is carried out at a temperature close to room temperature, which is particularly suitable for heat-sensitive components. The extraction process eliminates the possibility of oxidative and photoresponsive reactions, and the extract retains the natural flavor. Only one step from extraction to separation, the CO2 after extraction will not remain in the extracts CO2 is non-toxic, tasteless, non-flammable and easy to get and reused Fast extraction speed In recent years, supercritical extraction technology has got rapid development home and abroad, has realized the industrialized production in hops, spices, herbs, oils, petrochemicals, food health, and other areas.

1) Check power supply, electric wire to ensure intact. The power supply should be 3phase, 460V/60Hz. 2) Check refrigerator, ensure enough water in the water tank. 3) CO2 cylinder pressure not less than 5Mpa (Generally during 5-6Mpa). And CO2 cylinders should be full. 4) Check all pipeline joints and other joints. 5) Water tanks (for the heating jacket) should be fulfilled by water free of chloride/ Cl-. And tanks cannot be too full. The water level should be around 2cm distance to the cover of tanks. 6) The material kettle cannot be fulfilled too full. Raw material should be smashed into powder during 20-60mesh. If its size is less than 20mesh, it should be prilled no less than 20mesh. Also, its water content should be less than 10%. 7) Input material kettle into extraction kettle; input material kettle O-ring; input ventilation ring; install plunger; fasten clamps. 8) If co-solvent is used, add it through the co-solvent tank. Use the co-solvent pump.

| Various parts | Dimension(mm) |

| co2 pump | 1400*600*530 |

| Storage tank | 600*360*530 |

| Main chassie | 2760*0.83*1.76 (the height of rectifying column is 3000mm) |

| ooling system | 980*700*1400 |

| Extraction part | 1300*600*1320 |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What does BETTER need from me to quote a price?

a).Raw material

b).Production capacity per batch,we supply 0.5L~200L machine for you,big capacity of machine can be customized according to your request for your request.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops extract, Agarwood oil etc.

3.What is the machine material you use?

Stainless steel.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa.

5.Does the CO2 can be reused?

YES. CO2 can be used in circulation.

6.Does you machine can work under the conditions of supercritical and subcritical?

No, it can only work at supercritical state.

7. Can we do extraction test before purchasing?

Of course, we can do an extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order?

The Supercritical CO2 extract machine’s process flow is complex.Generally it takes about 60 workdays to Produce. We are responsible for the quality of the machine our customers. Every procedure and details have to be inspected strictly.

10. How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Miss Joyce:

---Your professional sales manager

Tel: +86-18917686969

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +86-2160518061,+86-2160519925

Mobile/whatsapp: +86-18917686969

Skype: joyceleejoe

Email: info@better-industry.com

Address: Bldg. 80, Liandong Ugu, Jiading District, Shanghai, China